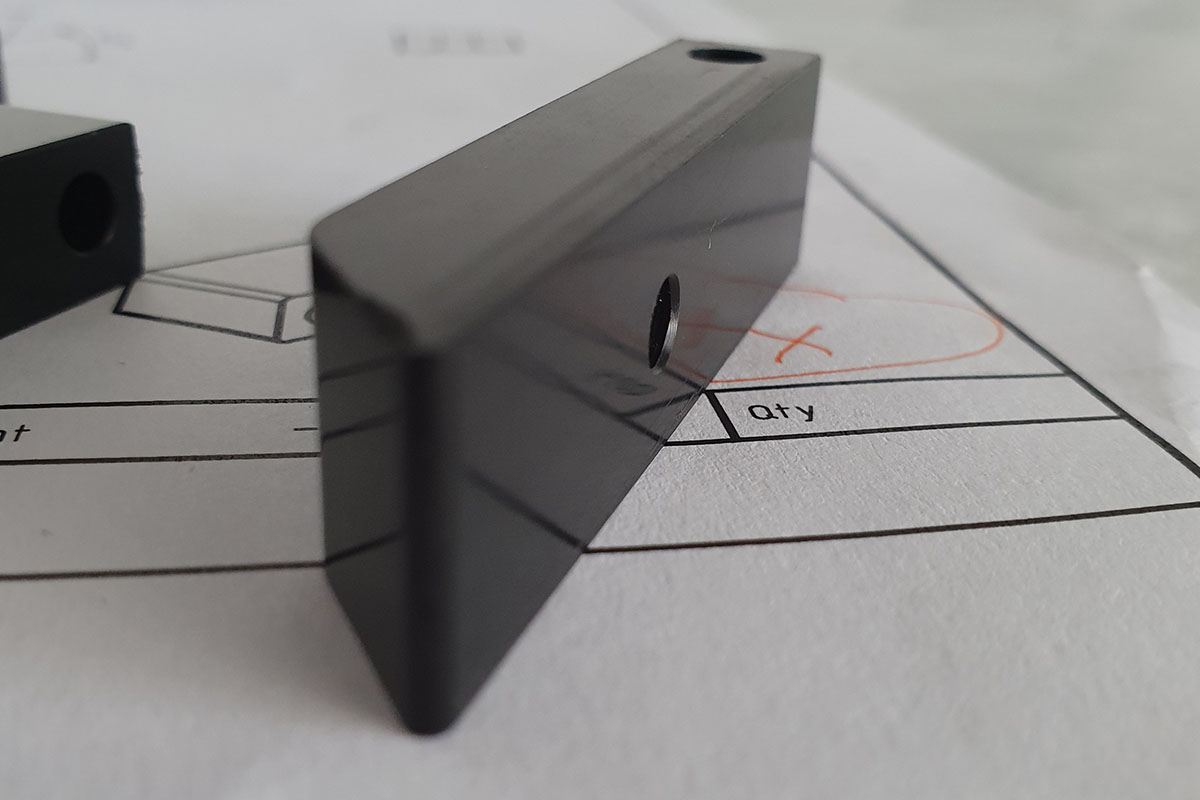

Manufacturing

We offer machining production technology with modern digitalised CAD/CAM technology on 1.600 square meters working area. The machine park includes CNC-controlled 3- and 5-axis milling machines and lathes for precise production up to a workpiece size of 1,800 x 2,000 x 1,100 mm and a workpiece weight of up to 5 tons.

Partnership network

Besides the manufacturing of components, the Installation of assembly groups, machinery and devices are also part of our portfolio. Our partnership network additionally offers various extending services like surface- and temperature-treatments as well as 3D printing.

Our Team of highly trained specialists stands for flexibility and dependability.

We ensure high quality of service and product as well as punctual delivery to our customers. Those are our priorities.

Our partner KerCon is available in house for 3D printing – we offer a virtual tour of our and KerCon’s premises. You can make this tour here:

Dual degree course

There is close communication with the Environmental Campus Birkenfeld on the development of magnet separators for Biotechnology.

The most recent project was about developing single-use-products for DNA-analysis with the help of magnet separation.

Together with becorp a new degree course was created to close the gap between technology and pharmacy. The eight-term degree course efficiently connects the classically scientific and technological education of a bachelor degree with a closely praxis related apprenticeship.

Our machinery

Manufacturing

Precise production on CNC-controlled 3 and 5-axis milling machines and lathes.

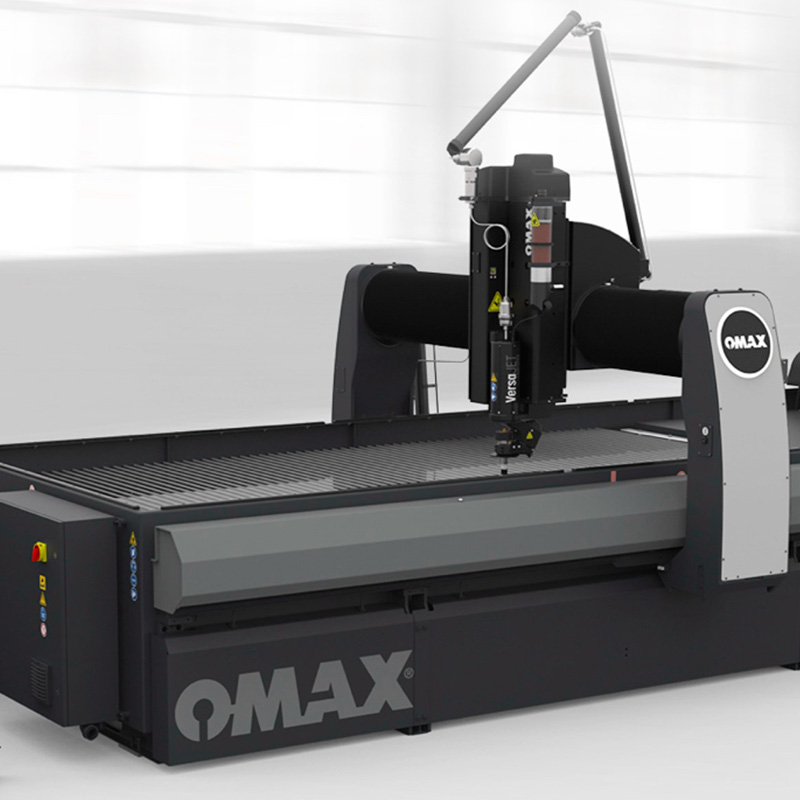

Omax OptiMAX 60X

Waterjet cutter

Omax OptiMAX 60X

Waterjet cutter

Traveling distance: 3302 x 1575

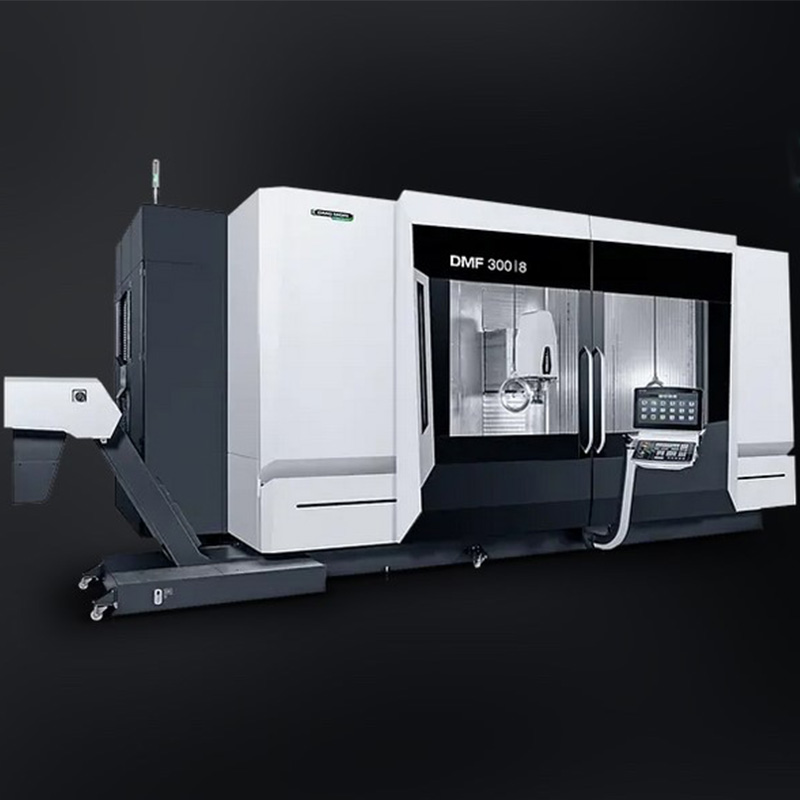

DMG DMF 300/8

5-axis-processing

DMG DMF 300/8

Traveling distance: 3000 x 800 x 850 (X,Y,Z)

Tool magazine: 90 tools

Spindle rotation: 15000

Tool holding device: SK40

Controls: TNC 640

Moving column milling machine of the latest generation for 5-Axis simultaneous processing

DECKEL MAHO DMU 200 P (5-Axis)

5-axis-processing

DECKEL MAHO DMU 200 P (5-Axis)

5-axis-processing

Traveling distance: 1.800 x 2.000 x 1.100 (X,Y,Z)

Tool magazine: 60 tools

Spindle rotation: 18.000 U/min

Tool holding device: SK-40

Controls: Heidenhain iTNC530

DMG DMF 260/7

5-axis-processing

DMG DMF 260/7

Traveling distance: 2600 x 700 x700 (X,Y,Z)

Tool magazine: 60 tools

Spindle rotation: 8000 U/min

Tool holding device: SK 40

Controls: Heidenhain ITNC 530

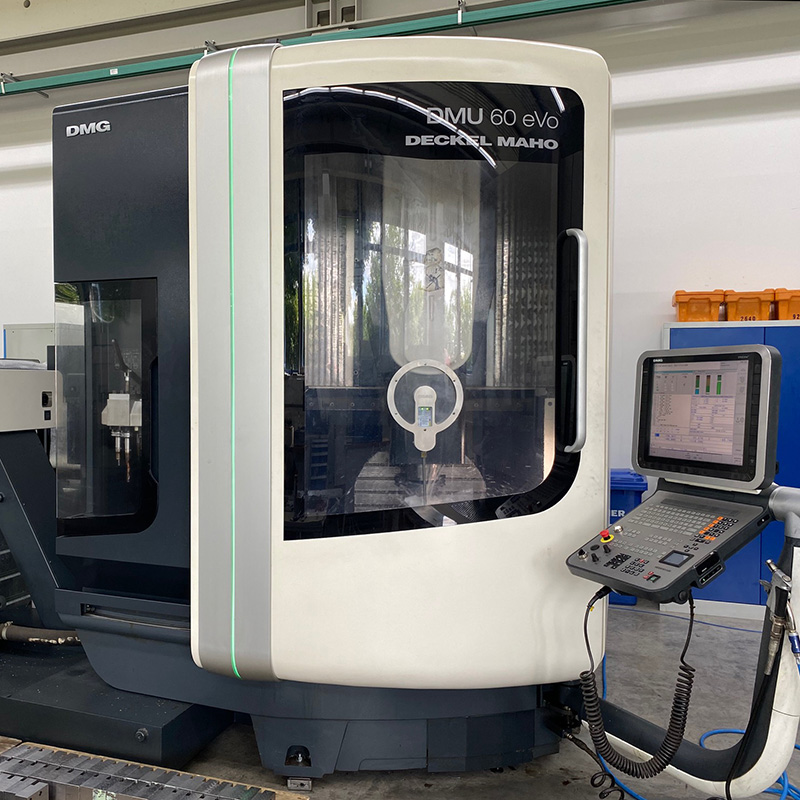

DMG MORI DMU 60 eVo mit Heidenhain iTNC 530

5-axis-processing

DMG MORI DMU 60 eVo mit Heidenhain iTNC 530

5-axis-processing

Traveling distance: 600 x 500 x 500 (X,Y,Z)

Tool magazine: 60 tools

Spindle rotation:18.000 U/min

Tool holding device: SK-40

Controls: Heidenhain iTNC530

DECKEL MAHO DMU 60 T (3-Axis)

3-axis processing

DECKEL MAHO DMU 60 T (3-Axis)

Precision tool device

Traveling distance: 630 x 560 x 560 (X,Y,Z)

Tool magazine: 24 Tools

Spindle rotation: 30.000 U/min

Tool holding device: HSK-e50

Controls: MILL plus

Gildemeister CTX 410

Rotary processing

Gildemeister CTX 410

Rotary processing

Rotary diameter: 200

Center point width: 500

Tool magazine: 12 tools./driven

Spindle rotation: 5.000 U/min

Controls: Siemens 840 D

Mikron VCE 1000 Pro (3-Axis)

Allrounder

Traveling distance: 1.020 x 560 x 600 (X,Y,Z)

Tool magazine: 24 Tools

Spindle rotation: 10.000 U/min

Tool holding device: SK-40

Controls: Heidenhain 426

Bridgeport VMC 800 (3-Axis)

Allrounder

Traveling distance: 800 x 440 x 300 (X,Y,Z)

Tool magazine: 22 tools

Spindle rotation: 6.000 U/min

Tool holding device: SK-40

Controls: Heidenhain